We talk a lot about the creation and manufacture of Apple products themselves. We know, for example, that the US-made Mac Pro is that iPhones, iPads, and most Macs are assembled in China at partner factories like Foxconn and Pegatron. But what about the disassembly / recycling of these products, how does it happen?

Tim Culpan of Bloomberg Businessweek, decided to investigate the matter and apparently Apple gives as much importance to the recycling process of these products as to their manufacture itself.

Everything happens at a Li Tong Group factory in Hong Kong, a 24-hour security site dedicated entirely to Apple. Neither Ma nor Li Tong Group let Culpan visit the facilities, let alone report details of the operation as a whole (quantity of units recycled, how disassembly was done, etc). But that doesn't mean Culpan didn't do his homework.

In this recycling business, the goal is to try to recycle about 70% of the weight of the devices produced. However, in a telephone interview, Lisa Jackson (Apple's vice president of environmental, political and social initiatives) stated that Ma far exceeds this target by 85 percent including recycling third-party products that some customers deliver to the company. This year Apple is expected to recycle around 9 million iPhone 3GS (model released in 2009).

To get an idea of the importance of such a recycling program, in 2014 Apple said it collected more than 40,000 tons of electronic waste, including enough to build 160 kilometers of rail line.

While global brands including HP, Huawei, Amazon and Microsoft also have detailed protocols for recycling their products, Apple's are the toughest and most demanding, according to the people involved in the lawsuits who didn't want to be identified because they're not allowed to. Talk about customers.

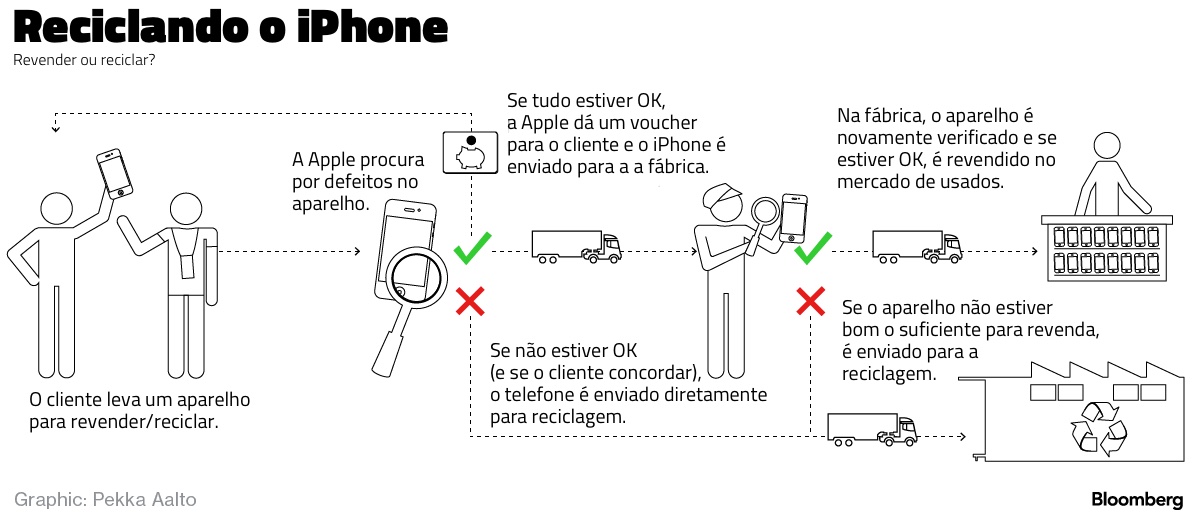

Here's how the recycling process goes, with Apple paying $ 100 to $ 350 for each device:

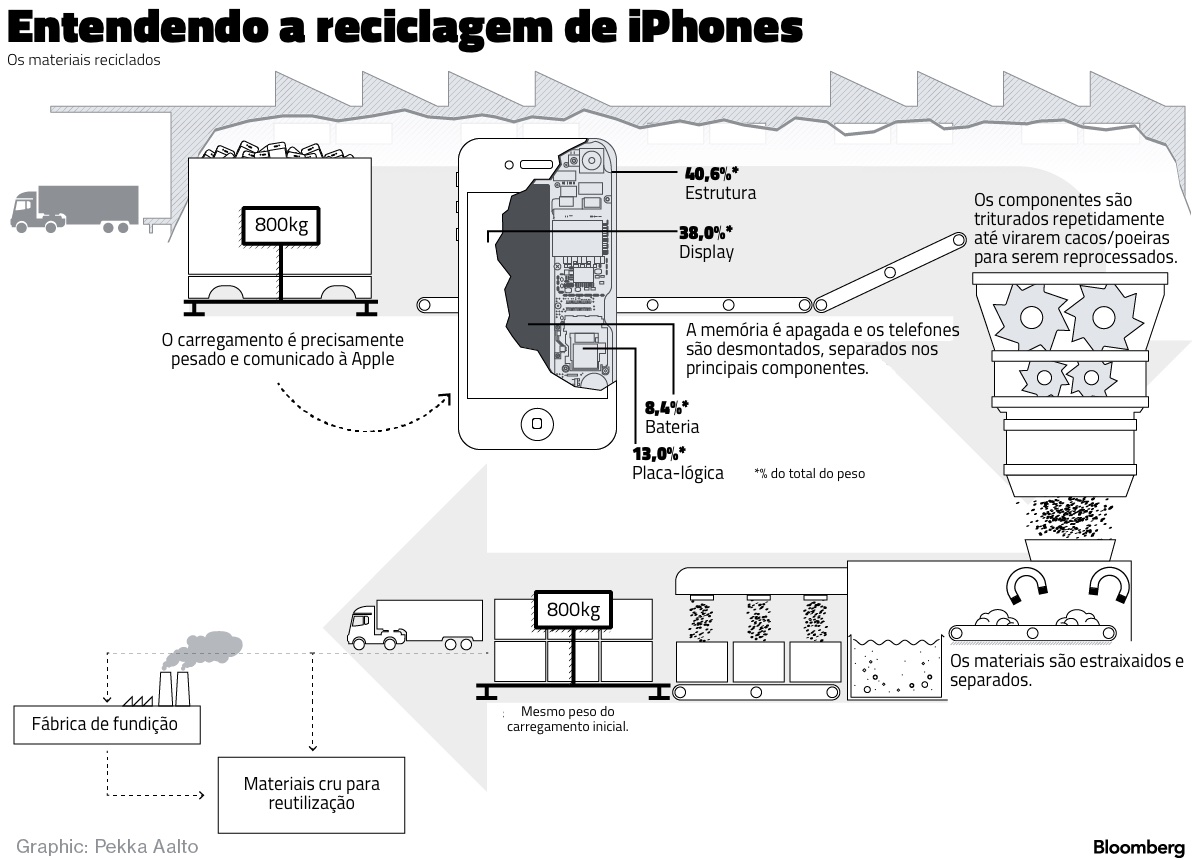

Recycled devices cannot be transported between regions, they must have their memory cleared and all logos removed. In the factory, scrap cannot be mixed with other appliances of other brands, so there is a Ma-specific factory with around 300 employees. In it, Apple's own workers monitor the process.

While some brands store components like chips that can be used to repair defective phones, Apple has a total destruction policy. Why does Apple go so far as to crush the pieces? To prevent fake products from appearing on the market, Jackson said. Once shredded, hazardous waste is stored in a licensed facility and recycling partners can extract other materials such as gold and copper. The rest are reused as aluminum window frames and furniture or glass tiles.

The company, however, is working on ways to reuse components in the future.

There is a problem of electronic waste in the world. If we really want to make the world better than when we found it, we have to invest in ways to go beyond what happens now.

Lisa Jackson, vice president of environmental, political and social initiatives at Apple.

Definitely, the person who believes that the role of the company goes until the moment of sale or, at most, even after-sale is badly mistaken.

(via MacRumors)